First roughly fix the position of the cable guide assembly.

.jpg)

As shown in Figure 2, position 1, release the cable connector.

Push the light rod indicated by the arrow in Figure 3. Make the state indicated by position 2 in Figure 2 close to the commutation. Then, as indicated by position 1, tighten the cable connector (1 is locked, 0 is loose).

.jpg)

Rotate the guide wheel adjustment screw at position 1 in Figure 1 to stop it in the middle position.

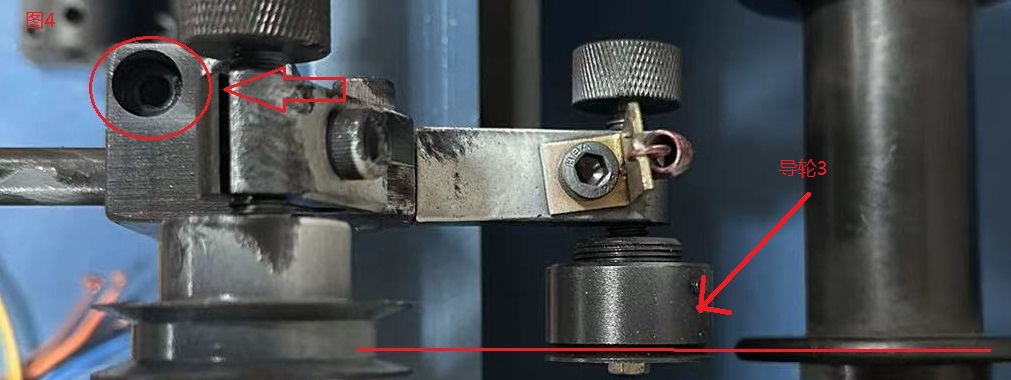

Loosen the screw in the circle in Figure 4, move the guide wheel group so that the groove of guide wheel 3 is on the same straight line as the edge of the parallel roller, as shown in Figure 4. Then tighten the screws in the circle in Figure 4.

After completing the above work, the machine can be turned on and idle.

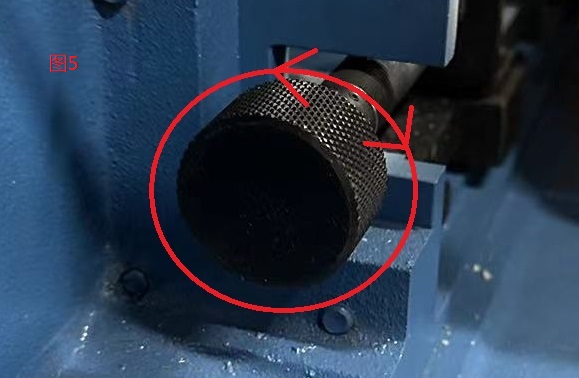

Adjust the width of the cable according to the swing as shown in Figure 5. Turn clockwise and widen; Turn counterclockwise to narrow.

Finally, hang the desired silk thread, adjust the width of the cable feeder, and make minor adjustments.

.png)